Since the word "fast fashion" was proposed in the last century, it swept the world with a rapid pace.After the formation of environmental protection, "fast fashion" has become a recognized area of decision makers of various countries.However, the industry chain of the textile industry has affected the continent. Although it has proposed environmental protection initiatives many times in the past 10 years, no effective specific measures have been seen.Recently, the European Union announced that it would implement plans for environmental protection regulations in the textile industry in 2030, but experts pointed out that the pace of "fast fashion" is still slow.

Europe's largest clothing retailer HM plans to sell second -hand clothing and accessories in London flagship stores from October 5th, which brings out the market and government policy pressure faced by the Fast Fashion industry.Under the premise of protecting the environment, the outside world requires that the textiles and clothing industry, which has a lot of contributions to the earth's pollution, can reduce the environment of the environment throughout the industry through recycling and reuse.

How to deal with climate change is one of the issues of the Twenty Group (G20) Summit held recently.The European Union had previously proposed to relieve the problem from the root cause.In May 2022, the European Union proposed some frameworks to restrict the abuse of earth resources in the textile industry. In June this year, it was adopted by the European Parliament.

EU measures are designed by 2030, companies selling textiles (clothes, mattresses, car interior, etc.) must meet certain standards in order to sell products to EU customers.This includes ensuring that the product is durable, does not contain harmful substances, and is mainly composed of recyclable fiber.Human rights in all aspects of the supply chain must also be protected. Manufacturers must be responsible for waste and cannot destroy the unprecedented or returned textiles.

European Member Pernille Weiss explained: "This is a overall plan, which shows how to make Europe a sustainable development in the textile field." She said that this strategy is still not binding.The next step is "reorganization and update the current instructions and regulations."Her group is studying up to eight such bills, including textile label regulations and waste frameworks. It is expected that the "first wave of new legislation" will appear after the EU election next summer.

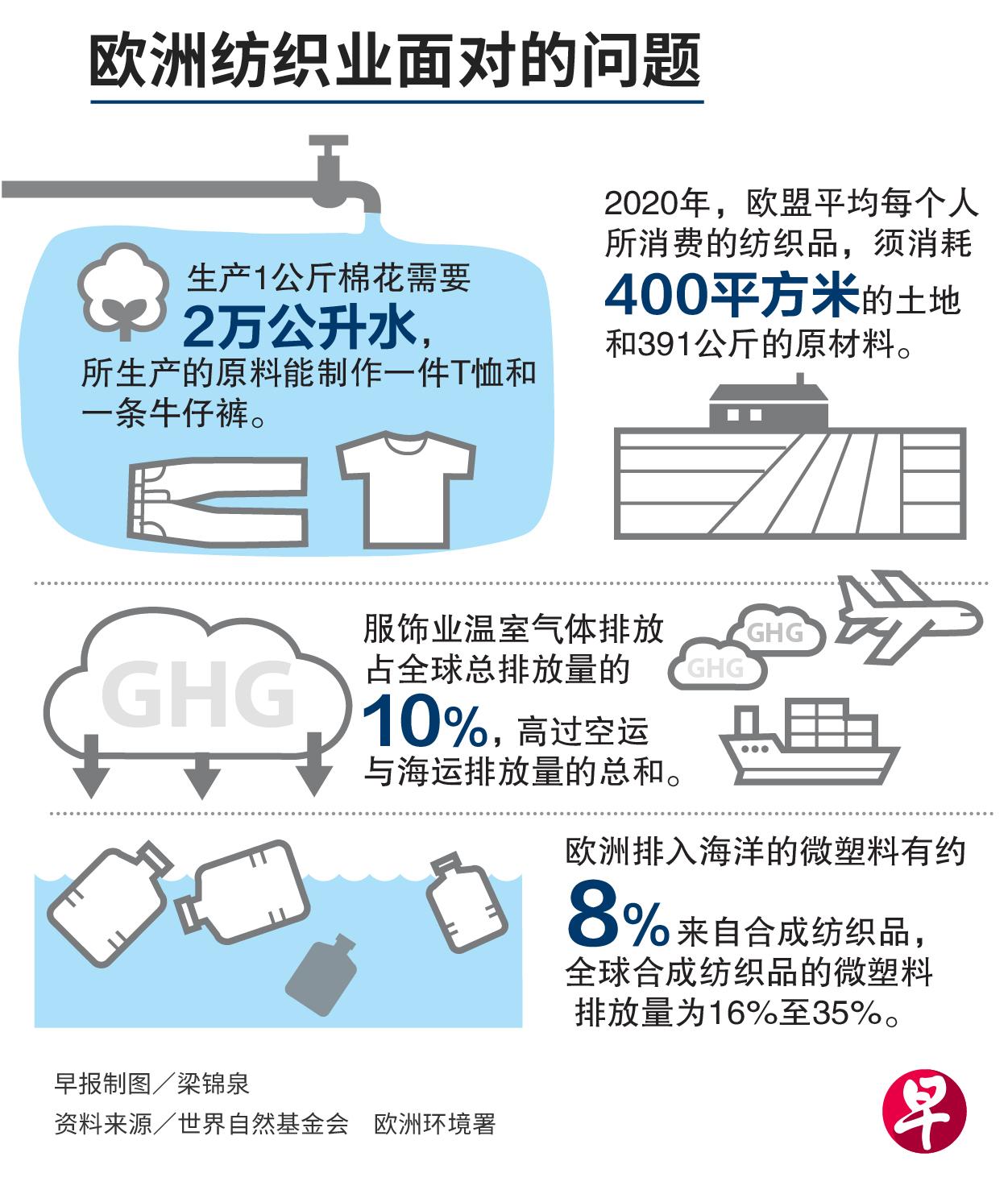

Even conservative estimates, the fashion industry is one of the major sources of pollution in the world.Textile production and use of the average impact on the environment and climate ranked fifth, only after housing, food, transportation and entertainment culture.

According to the Danish Organization "Global Fashion Agenda" data, the Danish organization, which coordinates the sustainable work of the apparel industry, data emitted by the textile industry accounts for 4.8 % of the global total emissions;%.According to the European Environment Agency data, nearly 75%of these greenhouse gases come from outside Europe, mainly in Asian textile production.

In terms of water consumption, textiles ranked third and ranked behind food and entertainment culture.As for the micro -plastic discharged from Europe to the ocean, about 8 % come from synthetic textiles; global, this ratio is estimated to be 16 % to 35 %.From the perspective of quantitatives, micro -plastic from textiles from textiles per year flows into the global ocean.

The think tank "Hot or Cool Institute", which aims to maintain public rights and interests, advocates changing the production and consumption of clothing to achieve the climate goals of the international community.The analysis of the institute shows that in the next seven years, the emissions of the fashion industry must be reduced by 50 % to 60 % to control the average temperature increase of the earth at the 1.5 degrees Celsius before industrialization.

Experts: Circular business model promotes brands and then uses waste products

Before the European Parliament made a decision, some European companies have abandoned Asia and chose to purchase raw materials in regions closer to Europe to improve competitiveness.In an interview with Lianhe Morning Post, SERAM Ramakrishna, a professor of mechanical engineering at the National University of Singapore, said in an interview with a joint morning newspaper that the nearest procurement of the Materials Circular Economy.In the short term, EU companies must make more efforts and resources to make this adjustment; from the mid -term, this will help improve the competitiveness of EU companies and differentiated competition with their opponents.

In order to make the fashion industry sustainable, experts suggest that the brand adopts a circular business model.This model prompts the brand to bear greater responsibility for the life cycle of the product.

This is different from the linear business model.Linear models transform resources into products and sell them later, and then products become waste; circular business models require brand and clothing manufacturers to use waste, residues and textile waste as much as possible.

The European Union has not yet set specific goals for the recycling ingredients in clothing.Before HM set up a second -hand product store, Spain's ZARA has gradually shifted to adopt renewal fibers and also set up second -hand clothing platforms for customers.

Sweden's environmental protection plan Siptex starts from recycling, classify textiles for recycling according to the color and fiber components.Renewcell, a Swedish textile recycling company, produces Circulose materials. It is a 100 % fabric made of textile waste. The raw materials come from shabby cotton jeans and cotton production waste.

Fast development of fast fashion industry

The pace of price increase of the parent company of ZARA, the world's largest fast fashion company, has slowed down, but the performance report announced on September 13 shows that the half -year net profit of this Spanish company increased by 40 %, exceeding expectations.

For about 20 years, fast fashion companies such as ZARA, HM and Mango have entered China and have expanded rapidly.In recent years, the situation has changed.The United States is the second largest source of Inditex operating income and the main source of income from HM.This trend also shows that, like many industries, the fashion industry has always stretched out an angle to explore the most favorable market.

The fashion industry is in interest.Lewis Akenji, the managing director of the Institute of "Hot or Cold Research", who is also a political economist, believes that to achieve the goal of the fashion industry emission reduction, the EU must set clear goals to reduce production excess and pollutant emissions, Restrict the use of artificial fibers, prohibit manufacturers from destroying unsold items, and gradually eliminate products with high per capita carbon footprints.

In addition to the European Union, the decision makers of the United States and other countries are considering legislation to expand the responsibilities of fashion brands in order to cover the impact of the entire life cycle and supply chain of the product.What they want to promote is the "EXTENDED PRODUCER Responsibility (EPR) model.

However, Akenji pointed out that the experience of EPR in the fields of electronic waste management and packaging shows thatThe definition of unclear policies will only transfer the burden from a wealthy country to a low -income country, and it will also promote the brand owner to transfer the responsibility to consumers, and perform "drift green" while increasing the profit of shareholders.

He believes that the properly designed EPR mode can achieve four key goals.First, improve clothing recovery and waste management.Secondly, ensure environmental destruction and waste management costs created by fashion brands to pay for supply chain transportation.Third, change clothing design and business strategies to ensure that the operation and product harm is small, and it is easy to recycle or return to nature.Fourth, to ensure the fair and fair operation of the entire industry, especially not allowing citizens of low -income countries to bear the dual burden of harsh factories and environmental pollution.

The fashion industry often focuses on achieving the first goal, because they only need to introduce technology to deal with after -sales or unprepared products, and they can make profitability as usual without changing their core strategies.Akenji said that the effective EPR model should achieve all four goals.

The raw material consumption of the textile industry and the waste produced

From 2000 to 2014, global clothing production has doubled more than double, and the speed of discarding is faster.The output of textiles produced by low -cost fossil fuels as raw materials has surged, and excessive consumption problems caused by the surge in the production of raw materials must be solved.Fossil fuel fiber such as polyester, regeneration polyester and nylon currently accounts for 62 % of global fiber output, and it is expected that this number will continue to grow rapidly.

The European Union seeks the textile industry to the circular textile economy, considering the implementation of policies with product environmental footprints (PEF) methods.However, this method is outdated, and it does not include important indicators such as micro -plastic pollution, plastic waste and cycle utilization.In short, it is difficult for the EU to manage things that it cannot measure.

The news website Politico.eu reports that the sewing of synthetic raw materials accounts for more than one -third of the world's major micro -plastic emissions. The EU should add these new indicators to PEF and give them 16 other 16The proportion of items is quite proportion to help consumers make choices and achieve the EU's goals.

The textile industry is inextricably linked, and the processing of waste is even more indifferent.CHTNA Prajapati, who studied permanent textiles at the University of Lafborg, said, said: "Cotton T -shirts include tags and sewing threads and other parts. These ingredients are usually made of polyester and other materials ...… The cotton yarn made into jeans is usually blended with elastic fiber, as well as other ingredients such as zipper, buttons and polyester sewing threads. "

It is necessary to effectively recycle and use it. At present, it is necessary to slowly classify by skilled labor, and the industry calls the recycling of "materials to materials".Therefore, for the clothing industry, it is a way to save money and incineration.

Of course, selling second -hand clothes online is already booming, but some people point out that this is just the way to pass the waste to others.

EU new rules shake the Asian textile industry

The new strategy of the European Union will shake the textile and garment industry, and it is expected to have a huge impact on the Asian industry. Asian manufacturers supply more than 70 % of the textiles required by Europe.

Dr. Lu Sheng, an associate professor at the Department of Fashion and Clothing Research of the University of Tellawa, pointed out: "New strategic significance is significant ... If the Asian company wants to sell products in Europe in the future, they must comply with many regulations listed by strategy."

A special report of Reuters quoted HM spokesperson that the company is working with 605 product suppliers mainly located in China and Bangladesh to implement changes to meet the requirements of the European Union.The Swedish giant purchased raw materials from 1,183 factories who hired 1.3 million employees.

There is not much response to textile export countries

Textile exporters realize that there is not much response time.Europe is the main export market of Indian clothing.Naren Goenka, chairman of the Indian Clothing Export Promotion Committee, said that it has now reached the point where the Indian textile industry decides whether to choose sustainable development.

Some Indian companies that care about the environment have made great progress.Take a agricultural cooperatives in Yavatmal, a agricultural cooperative in western India, as an example. As an example, it has grown cotton in organic ways in 2004. Now there are more than 15,000 farmers.

In Sri Lanka, the manufacturing department of the clothing manufacturer Hirdaramani Group has achieved net zero emissions. The next goal is to be halved by 2025, and at the same time, the use of sustainable raw materials will be used for perpetual raw materials.Rate to 80 %.

Ramatex, headquartered in Singapore's textile company, has a factory in many places in Asia to produce sportswear. The company participated in a research plan initiated by the non -profit organization "Forum for the Future".Fibrous clothing.

These companies are only one of the few examples to go to the EU goals.The "Future Forum" consultant Nicole Van Der Elst Desai said: "Some dawn is about to appear, and the manufacturer has invested in new technologies and has good results."

She said that one of the key to meeting the new EU standard is to have enough knowledge and skills."Manufacturers must first understand how to actively contribute to reducing the impact of the industry."

The European Union is the world's largest clothing import area. The five largest sources of product are China, Bangladesh, Turkey, Britain and India.Some Asian clothing manufacturers have called on brands to provide more help to adapt to new EU standards.

Professor of National University Luo Macolhona pointed out in an interview that China, Bangladesh and other countries did not study and develop fiber, yarn and textiles, nor did they invest sufficient investment in textile scrap solutions, such as textiles, such as textiles.Tracking and classification require advanced technology.The government can provide support in the use of sustainable raw materials and alternative raws, robots and automation, artificial intelligence and industrial Internet of Things (IIOT).

Roosmine is also the co -director of the National University Nannan Science and Nano Technology Program (NUSNNI) and serves as the chairman of the circular economy work group.He believes that decision makers must recognize that the textile industry and the fashion industry are undergoing transformation and inspire the industry to conduct innovation and upgrade through research.This means that they have to update the education and skills training programs to enhance employee capabilities.Governments of various countries must also update national standards and policy guidance.

Luo Machelline said: "In general, I think the transformation of the industry's recycling economy and sustainable industry in this industry is an ideal progress, which helps human well -being and the life maintenance system of the earth."

What is fast fashion?

Fast fashionFAST FASHION, also known as fast fashion, is a fashion clothing sales model. It is characterized by low prices, multiple models, and small quantities to stimulate consumers' interest.The industry provides consumers with current popular styles and elements to meet their consumer needs.Globalization and networking have accelerated the pace of fast fashion.

There is a saying that the term "fast fashion" comes from Europe in the 20th century.According to another statement, it was proposed by Donald Fisher, the owner of Gap in 1986 that it was used to refer to a retailer business model.model.

Fast fashion brands make rapid response according to the trend of clothing, quickly integrate popular elements, and pass to the brand store at the fastest speed for consumers to choose.In recent years, the rapid development of some multinational brands has also made fast fashion "run" faster.