In the summer of 1969, Shi Qin, 23 years old, Shiqin, at the ageTai took a flight to the United States, and he was flying towards a completely different world.

He grew up in a fishing village surrounded by sugarcane fields.Later, in Taipei, the capital of Taiwan, Taipei was a dusty city at that time. There were not many citizens with private cars.Now, he is going to study at Princeton University.

At that time, the United States had just sent humans to the moon, and Boeing 747 had begun to soar the sky.The US economy is greater than the economic sum of the Soviet Union, Japan, East and West, and France at the time.

Dr. Shi Qintai, now 77 -year -old, recalled: "When I landed in the United States, I was shocked. I thought: Taiwan is so poor, what I have to do to help it be better." and he did it.

Shiqintai later and a group of young people who were aspiring to transform an island of exported sucrose and T -shirt into an electronic industry hegemon.

Today's Taipei is wealthy and fashionable, and high -speed railways with a speed of 350 kilometers per hour cross the west bank of the island.The Taipei 101 Building has been briefly recognized as the highest building in the world, standing over the city, symbolizing the prosperity of the city.A large part of this is due to a tiny device that is smaller than the nails: Silicon Semiconductor, as thin as paper, now known for its chip chip.The chip is the core technology necessary for contemporary human life to use any tools, from iPhone to plane.

Can the microcomposter in Taiwan be against Mainland China?

Taiwan has now created more than half of the chip to promote contemporary human life.TSMC (TSMC), the largest chip manufacturer is the ninth largest company in the world.

This makes Taiwan almost irreplaceable, but also makes it fragile.

Because mainland China is worried that the outside world may cut off the supply chain of the most advanced chip and seek a replacement method

But in fact, Taiwan's road to "chip superstar" is not easy to copy.Because Taiwan has a "secret formula", which is trained by countless engineers through decades of hard work.In addition, this semiconductor chip manufacturing also depends on a network built above the economic connection, and the continuously upgraded American -China competition is now trying to disconnect these economic correlations.

Semiconductor is a globalized ecosystem, that is, the completion of a chip product. From raw materials, design, wafer manufacturing to foundry chips and seal testing, etc., it is often the collaboration between different companies in the world.But now countries hope to have their own ecosystems.

Shiqintai arrived in Prince, "The United States is starting to start the semiconductor revolution."

It was only ten years since the creation of "single chip circuit" from Robert Noyce. Integrating electronic components into single -chip silicon. This is the early version of the microcar and pushed the personal computer revolution.

During the two years after Dr. Princeton graduated, Shiqintai first designed a memory chip at the Burrows Corporation. The company was second only to IBM at the time and was the leader of the computer manufacturing industry.At the same time, after the oil crisis caused its exports to be severely damaged, Taiwan is looking for a new industry.Silicon seems to be a possibility. Dr. Shi believes that he can help: "I think it's time to go home."

In the late 1970s, he joined a new research experimental base composed of Taiwan's best electronic engineer.Great role.

Work began in Hsinchu City, a small city south of Taipei.Today, the area has become the global electronic industry hub, dominated by TSMC's huge manufacturing plant.Each of these chip factories is as big as several football fields, which are one of the most "clean" places on the planet.

The details of chip manufacturing are strictly protected secrets and are not allowed to enter.The latest factory "FAB 18" is located in southern Taiwan. It is a semiconductor factory invested nearly $ 20 billion. It will soon begin to produce three nanomi chips used in the next -generation iPhone products.

These achievements far exceeded Shi Qintai and colleagues' imagination in the experimental factory in the 1970s.The reason why they were optimistic at the time was that they had a technology authorized by a large American electronics company at the time, but what surprised everyone was that the performance of their Taiwan factory was better than blue.

In the 1970s, Taiwan entered the semiconductor industry in Taiwan in the 1970s.One of the leaders.

The reason is difficult to explain, and the accurate equations in Taiwan are elusive.

Dr. Shi's memories are relatively flat.He told me, "The output is better than the factory of the original US radio (RCA), and the cost is lower. Therefore, this makes the government believe that maybe we can do something."

The Taiwan government provided the initial funds, first to Lianhua Electronics, and then in 1987, it was injected to TSMC, which later became the world's largest chip foundry.Later, the government hired Zhang Zhongmou, a Chinese -American engineer, a senior director of the American electronics giant Texas Instrument Company.

This is a lucky or wonderful choice -today, Zhang Zhongmou, 93, is known as the father of the semiconductor industry in Taiwan.

At that time, Zhang Zhongmou quickly realized that competing with the United States and Japanese giants in existing games would fail.Therefore, TSMC only creates chips for others instead of designing its own chip.

After the "wafer foundry model" that rarely heard in 1987, the entire industrial structure changed the road, and it paved the way for Taiwan to become a semiconductor leader.

And the timing at that time was better.

Silicon Valley's new generation of startups, including Apple, Super, Qualcomm, and Nvidia at the time, there was no funding to build their own factories.It is difficult for them to find a manufacturer of chip that cannot be produced.

Shi Qintai said: "They would have to go to the leading semiconductor company at that time to ask them if they had extra production capacity to use. But TSMC appeared later."

Now, California's "non -factory company" can cooperate with Taiwan chip manufacturers, and the latter is not interested in stealing design or competing with the former.

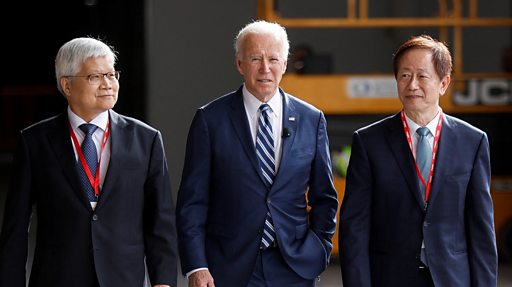

US President Biden and TSMC Chairman Liu Deyin (right right (right right (right right (right right (right right (right right (right right (right right (right right (right right (right right (right right (right right (right right (right right (right right (right right (right right (right right (right right (right right (right and right?)

The world produces more than one trillion (trillion) chips per year.The number of chips assembled on a modern car is between 1500 and 3,000.According to reports, there are about 1,400 semiconductor chips on the iPhone12.Due to the soaring demand for electronic products during the epidemic, the insufficient chip supply in 2022 affects the production and sales of washing machines to BMW Motor.

Taiwan can achieve extraordinary success in the industry: In this trillion chip, Taiwan's shipments are more than half, and almost all of the most advanced chips.This success comes from its huge production capacity. In other words, Taiwan's manufacturing is extremely efficient.

Because the manufacturing silicon chip is expensive and cumbersome.itBeginning with a "silicon crystal stick" composed of super pure silicon.And each silicon crystal stick may take a few days to make it, and the weight can reach 100 kilograms.

When the precision cutting machine cuts the thin silicon wafer into slender wafer, another machine also uses light to etch a tiny circuit on each wafer.A single wafer may contain hundreds of microprocessors and billions of circuits.

Including the Phoenix where TSMC is located, several large chip companies are not located in the bustling American central cities.

The final wafer yield is very important, that is, the ratio between the number of wafers that can be used to produce chips and the number of wafers that start processing in total.

In the 1970s, the wafer yield of American companies was as low as 10 %, and it was only 50 %.By the 1980s, Japan's average wafer yield reached 60 %.TSMC has surpassed all other companies at an 80 % wafer yield.Over time, Taiwanese manufacturers successfully stuffed more circuits into a small space.Using the latest extremely ultraviolet light micro -photographer, TSMC can etch 100 billion circuits on a single microprocessor, or more than 100 million circuits per square millimeter.

Why are Taiwanese companies so good at this?No one knows the exact reason.

But Dr. Shi believes that this question is easy to answer: "We have brand new machines and the most advanced equipment. We also recruited the best engineers.It is to introduce new technologies and learn lessons from our American teacher, and continue to improve, "he told me.

image source, Courtesy: itri

In 1977, Shi Qintai (second from the back row) returned to Taiwan shortly after returning to Taiwan.

Another young man who has worked in a large electronics company in Taiwan for many years also agreed.He said: "I think Taiwan companies are not good at making breakthroughs in technology. But they are very good at accepting the ideas of others and improved. This can be achieved by repeated trials and continuously adjusting details."

This is important because the machine needs to be continuously calibrated in semiconductor manufacturers.Manufacturing chip is engineering, but it is not just engineering.Some people compare it to cooking -like a delicious meal.Give two chefs with the same recipes and ingredients, and chefs with strong ability will make more delicious dishes.

In other words, Taiwan has a secret sauce recipe.

But the young man who did not want to disclose his name believes that Taiwanese companies have another advantage."Compared with the software engineer in the United States, even the best company here, the salary of engineers is quite poor," he said.

"But compared with other industries in Taiwan, the salary is pretty good. Therefore, if you work in a large -scale electronics company for a few years, you will be able to buy a house and car. You can still get married. Therefore, people endure it all."He said.

The gentleman also described the work of every Saturday with me, and the meeting started at 7:30 in the morning every day. The work usually lasts until seven o'clock in the evening.Moreover, if there is a problem in the factory, he will be called on Sunday or holidays.

"If people are unwilling to do this job, the company is over. It is because people are willing to endure that these companies can succeed." He told reporters.

Zhang Zhongmou, chairman of the front desk, will be described as expensive and wasteful in the United States to expand chip production last year, because manufacturing chips in the United States will be 50%more expensive than in Taiwan.

In December 2022, TSMC started a $ 40 billion factory in Arizona.This is a major change in the return of the US territory as a high -tech manufacturing industry.But since then, the title of the news has become a bit not positive.For example, the title of a news article is: "They are not obedient: the internal dilemma of Arizona chip factory", and the other is "TSMC faces a union counterattack, and it is difficult to recruit workers at the same time!"

chip production is scheduled to start next year.It is now postponed until 2025.

Zhang Zhongmou, chairman of the front desk, was deeply doubtful at the beginning.Last year, he will describe the production of chip production in the United States as "expensive and wasteful moves" because manufacturing chips in the United States will be 50%more expensive than in Taiwan.However, Taiwan's chip manufacturing strength has made it the center of the US -China science and technology war.

Washington hopes to prevent Taiwan from providing advanced chips to China, and worry that mainland China will use these chips to accelerate the development of its military and military and artificial intelligence industries.

Furthermore, Russia's invasion of Ukraine has caused European natural gas supply to be tight, and American politicians are uneasy about the situation in Taiwan.They are worried that the production of high -end chips is mainly concentrated in Taiwan. Once China enters, the US economy will become birds in the cage.

However, Taiwanese companies believe that the production of production will lack economic benefits.They just do so under political pressure.

Because of its own success, it should even weaken the industry that is regarded as the "Silicon Shield" -such a statement that makes Taiwanese feel indignant.At the same time, countries around the world are swaying whether it is worth protecting this island and its democratic society.

Shi Qintai said that those who try to force the reorganization of global chip production have misunderstood the core behind the success of the industry: "If you look at the history of semiconductors, no country has dominated this industry, Taiwan may dominate the manufacturing industry, but the supply chainLong, each part of its innovation helps the industry to grow. "

For example, most of the global silicon ore comes from China, although most of them are used in the solar industry.Germany and Japan are in a leading position in dealing with wafer.CARL ZEISS manufacturing optical parts are provided to the production chip lithography machine and ASML from the Netherlands.And this tedious manufacturing follows the design of the ARM Holdings, a US company or headquarters headquartered in Cambridge, England.

Dr. Shi expressed his doubt whether he could rebuild this supply chain in China (from raw materials to design to high -end production): "If they want to create a different model, I wish them good luck," he shrugged.

He added, "Because if you really want to innovate, you need everyone from all over the world to work together. This is not what a company or a country can do."

Image source, ethan Lin

TSMC's factory in Phoenix

But he also doubts about excluding China like the United States.He said, "I think it may be a major mistake!"

"Looking back in the past, I am lucky to witness the extraordinary growth and long -term peace of Taiwan. Now I see the conflict elsewhere in the world, I am worried that it may affect Asia. I hope people can cherish the valuables we have paid.Work hard, don't destroy it. "