Hong Kong South China Morning Post Monday (September 25)It is reported that China is planning to use a new type of particle accelerator light source to build a large factory that accommodates multiple optical machines to achieve localization of chip manufacturing.

It is reported that the single particle accelerator planned by China has two basketball court size. At present, the Tsinghua University team is discussing with the Hebei Xiong'an New District Government to finalize the construction location for this project.

The report also quoted scientists that this technology can surpass the US sanctions in the United States and become a new leader in the semiconductor chip industry.

What is new technology?

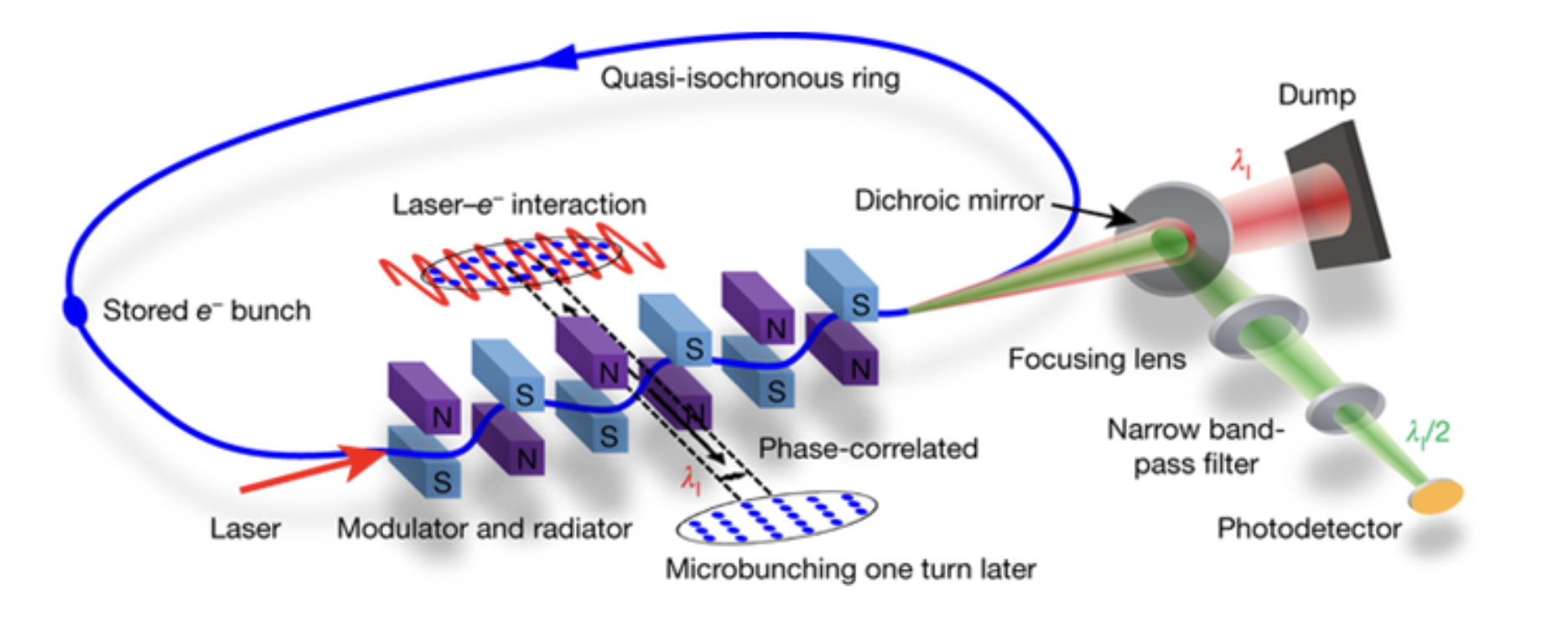

The new type of light source technology in China is full name "Steady-State Microbunching (SSMB), which is simply using the energy released by the charged particles in the acceleration process as the light source as the light source., Generate extremely UV light (EUV).

The well -known EUV light engravings are the optical light technology of the ultraviolet light with a wavelength of 10 to 14 nanometers.At present, the world's use of extremely ultraviolet light machine manufacturers alone in the Netherlands semiconductor equipment manufacture giant ASML (ASML).

This also explains why China's steady -state micro -concentration technology has a breakthrough. In the past few days, it has caused heated discussions on the Internet of China.Some media have even said that China has mastered the core technology of the light carved machine, which can "overtaking and face Acemai."

However, steady -state micro -concentration is not the technology that has only appeared recently.

The concept of steady -state micro -gathering beam was first proposed by Professor Zhao Wu and his doctoral student Daniel Ratner, a professor of Tsinghua University at the University of Stanford and the outstanding visiting professor of Tsinghua University.Zhao Wu was a student of Yang Zhenning, a well -known physicist in China.

Zhao Wu is committed to promoting the research and international cooperation of steady -state micro -concentration. In 2017, he led with Professor Tang Chuanxiang, a professor at the Department of Engineering and Physics of Tsinghua University to conduct experiments with the German Research Institute.

After four years of research, Tang Chuanxiang's cooperation team and Germany's cooperative team in February 2021 published an experimental demonstration entitled by the principle of steady -state micro -beam (Experimental Demonstration of the MechanismThe research papers of of Steady-State Microbunching reported the first principle verification experiments of steady-state micro-concentration.

Based on the principle of steady -state micro -concentration, it can obtain related radiation light with high power, high -weight, narrow bandwidth, and wavelengths can be covered from Taihez to extremely ultraviolet bands, including extremely deep ultraviolet lightThe 13.5 nanometer wavelength EUV light required for the carving machine.

The first author of the paper, Deng Xiujie, a doctoral student at the Department of Engineering and Physics of Tsinghua University, said in an interview with the 2021 Science and Technology Daily reporter: "One of the potential applications of steady -state microstructure light sources is the future EUV light carving machineLight source, this is also an important reason for the international community to pay attention to our research. "

What are the advantages of a steady -state micro -concentration?

The South China Morning Post reports that compared with the current Asmore's extremely ultraviolet light technology, the steady -state micro -concentration is a more ideal light source. The reason is that the latter has higher higherThe average power, higher chip output, and lower unit costs.

It is reported that Asmi uses laser plasma to generate extremely ultraviolet light sources and project strong laser pulses to liquid tin drips.Laser crushes liquid tin droplets, generates extremely ultraviolet pulse light during the impact, and generates an extremely ultraviolet light source with a power of about 250 watts after complex filtering and focusing.

Before reaching the chip, the extremely ultraviolet light beam must be reflected by 11 mirrors. Each mirror will lose 30%of the energy. Therefore, the power when the beam reaches the wafer is less than five watts.This will become a problem when manufacturing a chip with a 3 -nanometer to 2 nanometers.

But the steady -state micro beam technology avoids this problem.The steady -state micro -concentration beam realizes a higher output power of one kilowatt, plus its narrow bandwidth, and less reflectors, so it can generate higher terminal power.

Why suddenly received attention?

The papers published two years ago have received a lot of attention, and it has a lot to do with Huawei's breakthrough on the chip.

Huawei released the latest flagship mobile phone Mate 60 Pro at the end of August. After disassembling professional agencies, it was found that it was equipped with a new type of Kirin 9000S chip and was made by Chinese enterprises SMIC.Chip technology.

Huawei broke through the multiple sanctions of the United States since 2019, and quickly caused the United States to be vigilant and triggered the investigation of Huawei mobile phone chips in early September.

Although the results of the US survey show that there is no evidence that Huawei can make 7 nanometer chips on a large scale, the US Department of Commerce still announced the final execution of the US chip and the science bill last week (September 22).Details to ensure that Washington provides subsidies for the US semiconductor industry and manufacturing industry, and will not benefit China and other countries that are regarded by the United States as national security.

In the context of the increasingly refined technological blockade of China and the United States for the Chinese and American chip warfare, the steady -state micro -clustering beam suddenly "fire" suddenly, how many Chinese Internet users behindAfter seeing that China has made breakthroughs on mobile phone chips, it can also take advantage of the hope of progress in the field of optical machines.

The "Fire" is also the "Thirteenth Five -Year Plan" planned High Energy Photon Source project, which is included in the "Thirteenth Five -Year Plan" planned.

The pictures of the HEPS project were mistaken for the steady -state micro -concentration project of Tsinghua University, and were reposted many times on Weibo.

Can it solve the "card neck" of Chinese chips?

According to the South China Morning Post, after the release of the papers of steady -state gathers in 2021, it has continued to advance in the past two years.In 2022, the research team designed another model at Tsinghua University.

It is reported that Pan Zhilong, a member of the team member and the teacher of the Department of Engineering and Physics of Tsinghua University, said at an academic seminar last January.Hua University has designed the power of the ultraviolet light source of one kilowatt stabilization micro -gathered beam, and some key technologies are close to maturity.At a special meeting held in Xiong'an in February this year, Pan Zhilong also demonstrated the efforts of the Tsinghua University team to push the steady -state micro -concentration technology to the industry practice.

Nevertheless, Tang Chuanxiang said in the report of Tsinghua University that there is still a long way to go to the independent research and development of extremely UV light engraving machines.

He believes that the extreme ultraviolet light source based on steady -state micro -concentration is expected to solve the core "stuck neck" problem in independent development of the optical carvings, but this requires the persistence of the steady -state micro -polar ultraviolet light source for the continuous continuous ultraviolet light sourceTechnology research also requires the cooperation of the upstream and downstream industrial chain to achieve real success.

The "Made in China", which has tens of millions of fans, also analyzed that the real difficulty is a set of nano -industry industry chains behind the light carved machine.A light carved machine has 100,000 parts, from 5,000 suppliers worldwide, and all parts of the entire machine must reach nano -level accuracy.

China's micro -clustering pole ultraviolet light source particle accelerator has not yet been completed. Even after completion, it cannot only rely on light sources.Each part of each part.

Caixin.com also reported on September 21 that the steady -state micro -concentration is still a cutting -edge optical technology research, and there is still a distance from the realization of the optical carvings system.

The report quotes a unknown associate professor in an integrated circuit in China that the technology only verifies the principle that the principle is feasible, and subsequent engineering and industrialization still need to solve a large number of unknown problems."This technology is just an exploration of different routes, but now I hope what kind of practical effect it can produce is early."Did you engrav the machine?calm!The article also said that the principle of the new light source is still in the primary verification stage, and there is still 15 to 20 years before the real and practical less.Thousands of miles.

Throughout the above, there is still a large gap between the breakthrough technology and the production of the light engraving machine.Faced with the continuous blocking of the United States, China's semiconductor industry still has a long way to go on the road to catching the West, and the West will not stagnate.Scientific research can only seek truth from facts, not to mention the production of lithography machines. This is one of the most complicated machines built by human beings. In addition to independent innovation, it also needs upstream and downstream industrial chains and cross -national cooperation to explore the best solutions.